Dry-pressed tiles and wet-formed tiles

This article introduces the basic processes of tile forming and firing. Tiles can have different characteristics depending on how they are formed and fired. In certain situations, it may be necessary to choose the appropriate type based on the installation location or specific conditions.

Table of Contents

■ Tile Production and Forming Techniques

There are various types of tiles, but most of them are mainly manufactured using either the dry-press method or the wet-forming method.

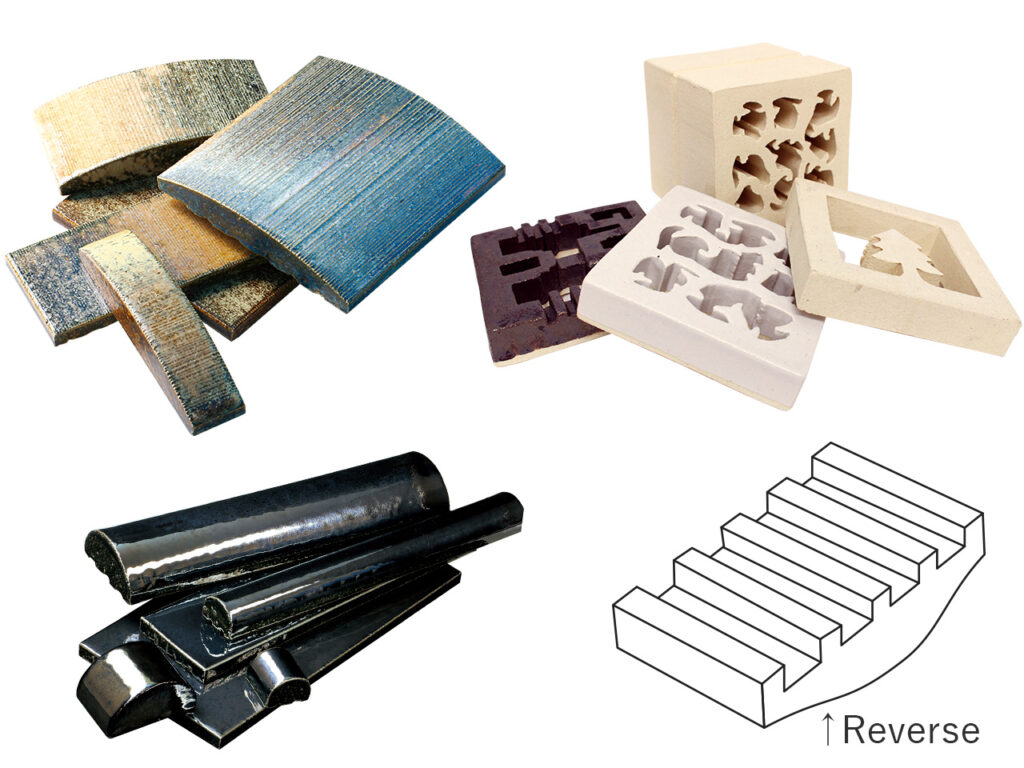

Dry-press method / Dry-pressed tile

The dry-press method shortens both drying and firing times, leading to high dimensional precision and consistent quality. As the clay body is pressed in a mold, tiles typically have a smooth and uniform appearance. However, recent advancements have made it possible to achieve textures similar to those of wet-formed tiles. This method is well-suited for low-cost, large-scale production.

Dry-pressed tiles can be identified by molded imprint on their reverse, a result of the pressing process.

| Dry-Pressed Tiles Manufacturing Process | |

|

1. Raw Materials The raw material, known as kairado, is a clay powder mainly consisting of blended and processed stone. |

|

2. Forming The kairado powder is filled into metal molds and compacted using a high-pressure press to form the tiles. |

|

3. Glazing The glaze is applied using a spray technique. Note: Glaze is a vitreous material applied to the surface of tiles to seal the porous body, preventing absorption of water and other liquids, and to provide decorative and aesthetic finishes. Note: In the case of unglazed tiles, this step is omitted. |

|

4. Loading into the Kiln The formed, unfired clay bodies are vacuum-lifted and stacked in saggars (refractory trays). |

|

5. Firing Globally, continuous roller hearth kilns—where products are transported on ceramic rollers—are more common and complete firing in 30 minutes to 2 hours. In Japan, however, tunnel kilns are typically used, where products are slowly moved on carts through the kiln over a period of 20 to 40 hours. |

Wet-forming method / Wet-formed tiles

The wet-forming method is valued for imparting the unique character and warm expression typical of ceramic products. Due to the higher moisture content in the raw materials, firing often causes shrinkage and deformation. However, these slight variations create the individuality and texture that give ceramics their distinctive charm and appeal.

Wet-formed tiles can be identified by their extrusion forming process, which results in the reverse not having a stamped pattern but instead displaying striated grooves.

| Wet-formed Tiles Manufacturing Process | |

|

1. Raw Materials The raw materials are kneaded to create a clay body with a moisture content adjusted to 20–25%. |

|

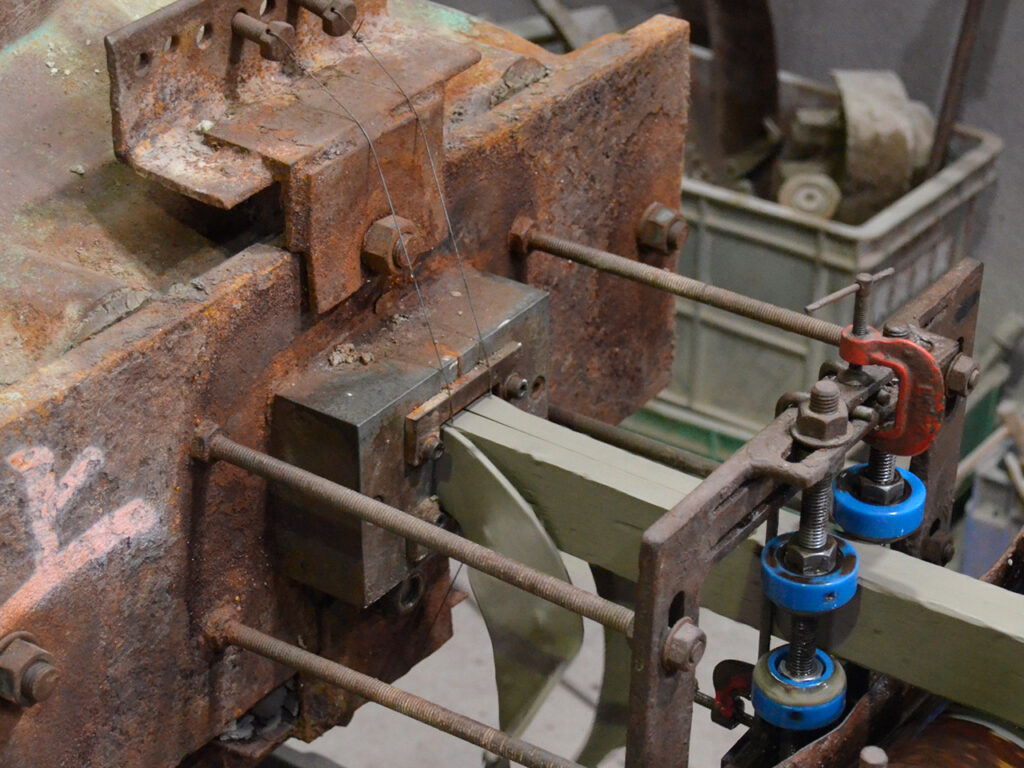

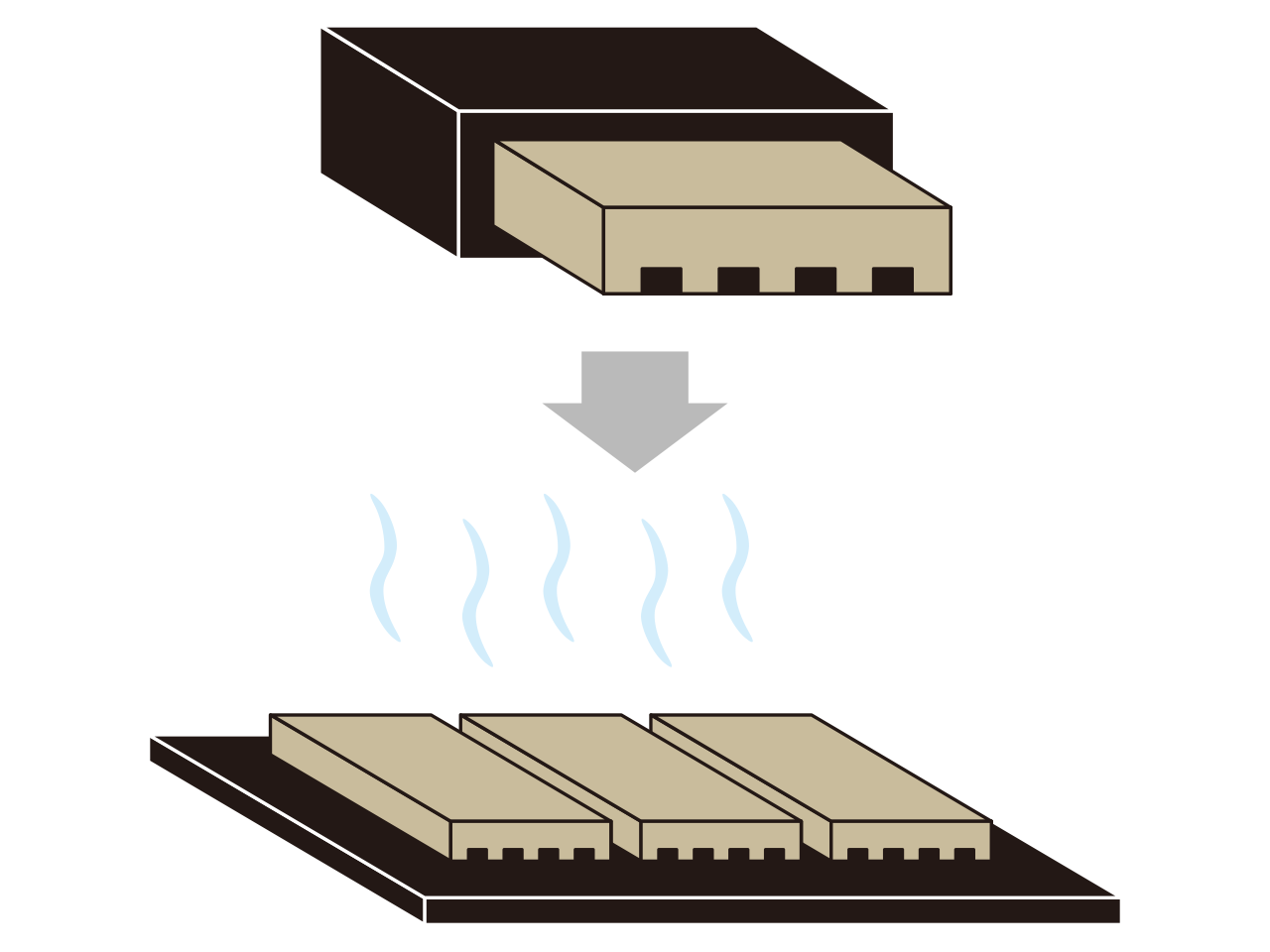

2. Forming The clay body is extruded using a vacuum extrusion machine, producing slabs that are then cut to the desired size with fine steel wires. After cutting, the slabs are manually arranged on racks for drying. |

|

3. Glazing A ceramic glaze is evenly applied to the surface using a spray system. Note: Glaze is a vitreous material applied to the surface of tiles to seal the porous body, preventing absorption of water and other liquids, and to provide decorative and aesthetic finishes. Note: In the case of unglazed tiles, this step is omitted. |

|

4. Loading into the Kiln The formed unfired tiles are manually arranged on kiln shelves. Refractory shelves and props are used to create height between the shelves during kiln loading. |

|

5. Firing The tiles are slowly fired over 20 to 40 hours while being transported on carts through a tunnel kiln. |

■ Differences in Firing Methods

|

Oxidation FiringOxidation firing is a method that ensures good ventilation in the kiln, providing an ample supply of oxygen. Air flows smoothly from the kiln interior to the chimney, drawing in fresh outside air. During this process, the oxidizing metals in the glaze and clay body combine with oxygen, transforming into different compounds that develop color. This method produces relatively stable and consistent colors. |

|

Reduction FiringReduction firing is a method that limits the supply of oxygen to the kiln, causing the firing material to draw oxygen from within itself. This is achieved by reducing the airflow to the chimney and minimizing the intake of outside air. Depending on the firing conditions, subtle color variations occur, producing the characteristic color range and effects known as ‘kiln variations’ typical of ceramics. |

■ Tile Classification according to

Japanese Industrial Standards (JIS) A 5209:2008

Classification Based on Production/Forming Techniques and on Water Absorption Rate

| Type I: Porcelain (Water Absorption Rate 3% or less) |

Type II: Stoneware (Water Absorption Rate 10% or less) |

Type III: Earthenware (Water Absorption Rate 50% or less) |

|

| Wet-forming method (Type A) | Type AI | Type AII | Type AIII |

| Dry-pressing method (Type B) | Type BI | Type BII | Type BIII |

Note: Classification according to JIS A 5209:2008

■ Summary

In this article, we introduced the basic tile production methods, focusing on the dry-press and wet-forming techniques. We explained how each method influenced the tile’s texture, precision, and overall character. We also compared oxidation and reduction firing methods, highlighting their impact on color and finish. Finally, we presented the Japanese Industrial Standards (JIS) classification system, which grouped tiles by forming method and water absorption rate.