About Tile Surface Textures

In previous articles, we introduced how tiles can vary in appearance depending on whether they are glazed or unglazed. We also looked at different manufacturing methods and firing processes. In this article, we will take a closer look at tile surface textures.

Surface texture plays a vital role in both the look and performance of tile products. Different forming methods—whether wet extrusion or dry pressing—offer distinct advantages and allow for a variety of unique textures and precise finishes. Below, we’ll explore the key features and texture options available with each of these techniques.

Table of Contents

■ Dry-Pressed Tiles

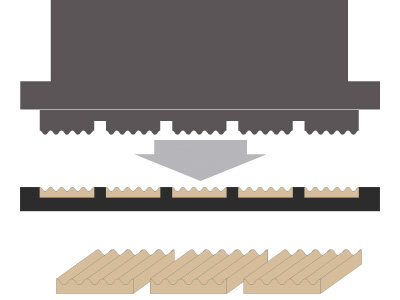

| Dry pressing is the dominant forming method in the global tile industry. It involves compacting low-moisture clay under high pressure using precise molds, making it ideal for mass production. This process ensures speed, consistency, and suitability for large-format tiles commonly used in modern flooring and wall applications. It is also the primary technique for producing porcelain tiles, which are valued worldwide for their strength, low water absorption, and clean appearance.When combined with patterned metal molds, dry pressing can also produce refined relief-style surfaces with excellent dimensional precision. While this method is highly effective for flat and moderately textured tiles, it is less suitable for thicker formats or deeper, more sculptural designs. Several examples are shown below to illustrate the types of reliefs achievable with this technique. |

|

|

|

|

|

|

|

|

|

|

|

|

|

■ Wet-formed Tiles

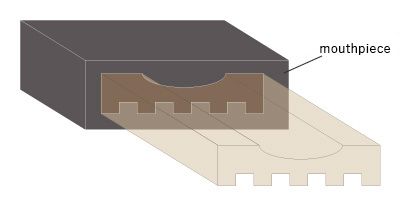

| Wet forming is a technique deeply rooted in Japanese tilemaking, especially in traditional and artisanal production. The use of high-moisture clay offers greater flexibility during shaping, making it ideal for creating complex profiles, expressive details, and richly textured surfaces.When carried out using a vacuum extrusion machine, it enables the consistent formation of thicker tiles with uniform cross-sections. After shaping, various finishing techniques can be applied to achieve a wide spectrum of visual effects—from bold reliefs to subtle, refined textures. Rooted in regions like Tajimi, this method continues to define the tactile and aesthetic character of Japanese ceramics. |

|

|

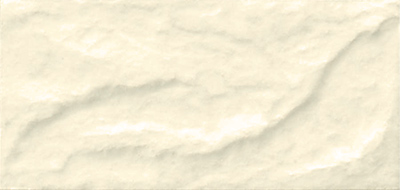

1. Flat surface A flat surface formed from raw materials with a low content of aggregates such as chamotte. |

|

|

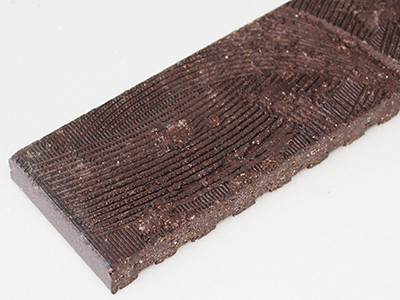

2. Rough surface During extrusion molding, the surface layer of the raw body is peeled off. Depending on the size of the chamotte particles, the surface can become rough and scratched in appearance. |

|

|

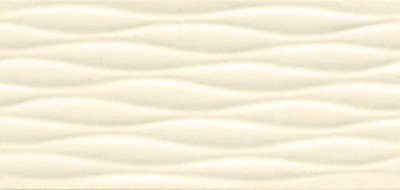

3. Rolled surface During extrusion molding, patterns such as stone textures or wave surfaces are applied using patterned rollers. |

|

|

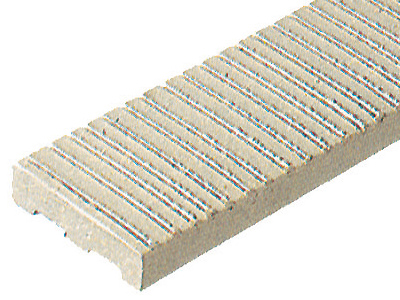

4. Scratch surface A nail-like tool is set on the die of the extrusion machine to scratch the surface during forming. |

|

|

5. Brushed surface Random patterns are manually applied to a flat raw surface. |

|

|

6. Crafted surface A layer of clay is applied to the surface of the raw body to achieve a natural and textured finish. |

|

|

7. Blasted surface After firing, the surface is roughened by blasting with steel balls, sand, or other abrasive materials. |

|

|

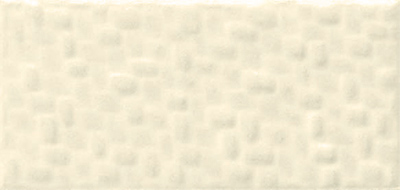

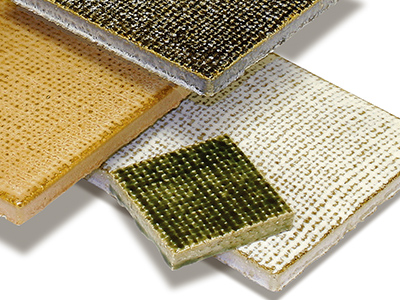

8. Fabric-like surface The design is created by pressing hemp cloth onto the raw tile surface, resulting in a distinctive patterned texture. |

|

|

9. Chipped surface The dried tile base surface is coarsely chipped with chisels or similar tools to create a textured finish. |

|

|

10. Split-face surface Formed by breaking the dried base material in half, then firing it to preserve the natural fractured surface. |

|

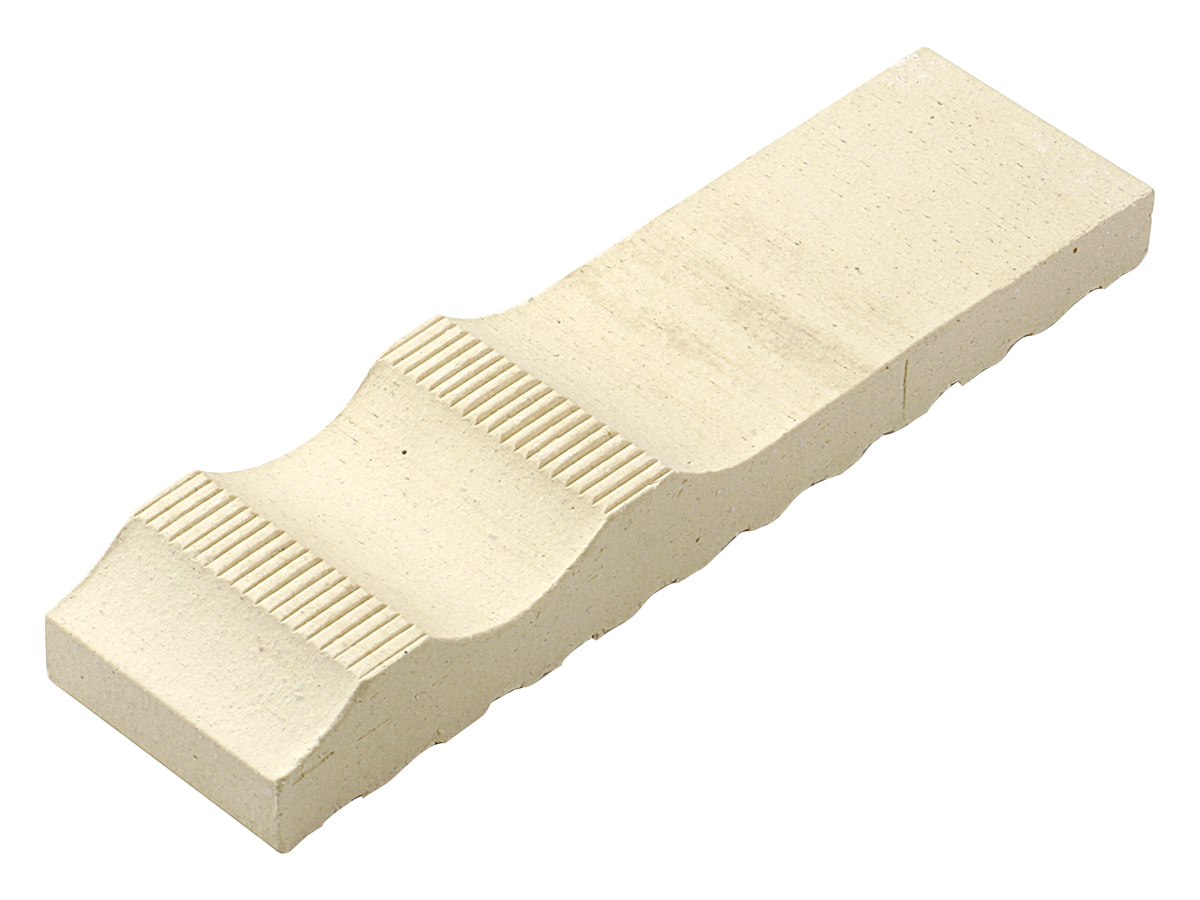

Special Surface Textures of Wet-Formed Tiles

By adjusting the shape of the extrusion die, we can create tile surfaces with bold textures and a strong sense of depth. These uniquely contoured finishes add a striking three-dimensional quality. When combined with additional surface treatments after shaping, the design possibilities become even more diverse.

|

|

|

|

|

|

|

|

■ Summary

The art of tile-making offers endless design possibilities through the combination of forming methods, glazing techniques, surface treatments, and firing processes. Each step contributes to the depth and character of the final product.

As we continue to explore these techniques, we look forward to sharing the rich beauty and versatility of Japanese tiles with a wider audience around the world.