- Home

- Story

Characteristics of

Japanese Tile

Our Japanese tiles are slowly fired at over 1200°C in a tunnel kiln overnight. The baked tiles feature natural color variation, created by a fusion of flame and glaze during high-temperature firing in the kiln.

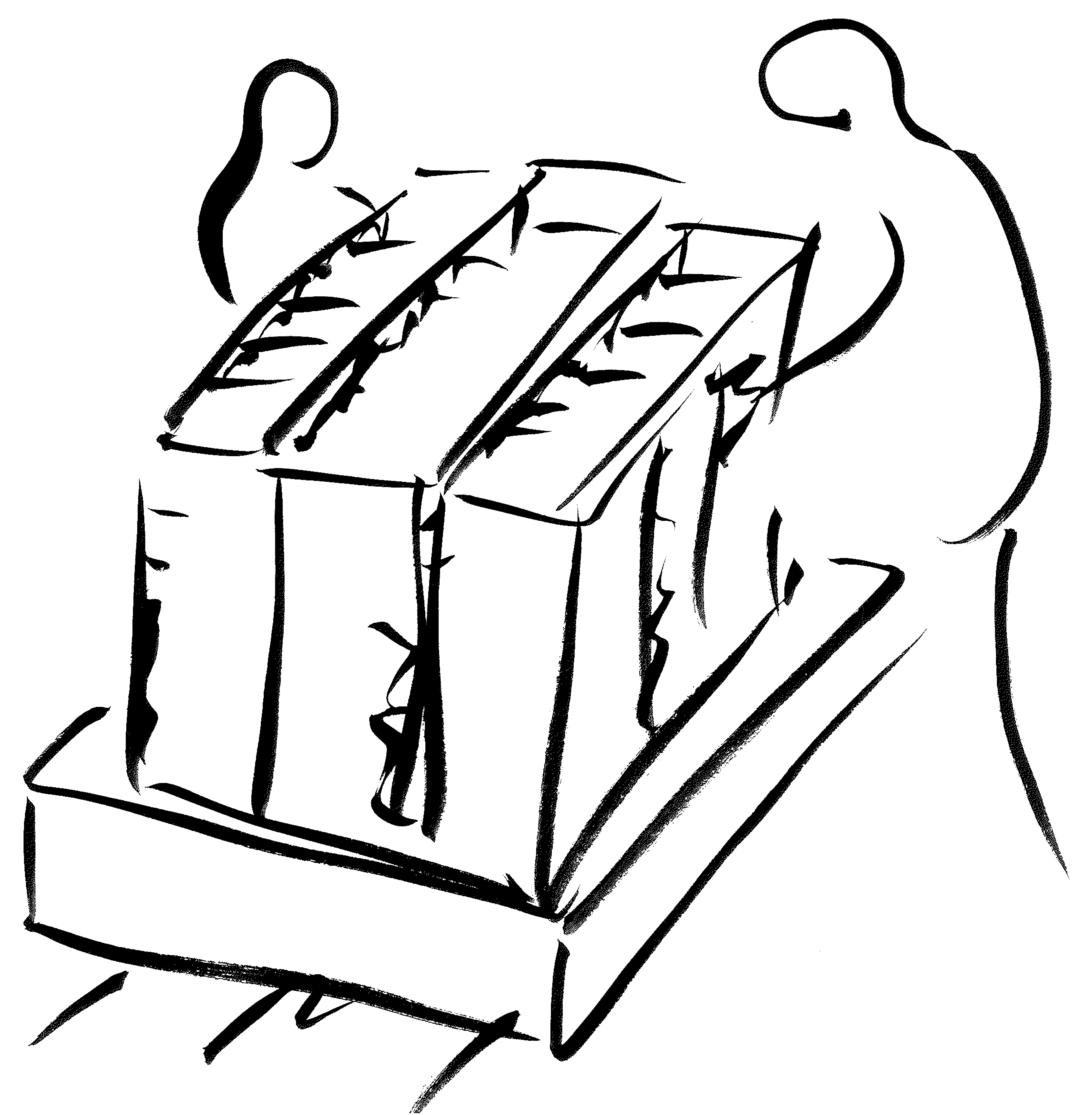

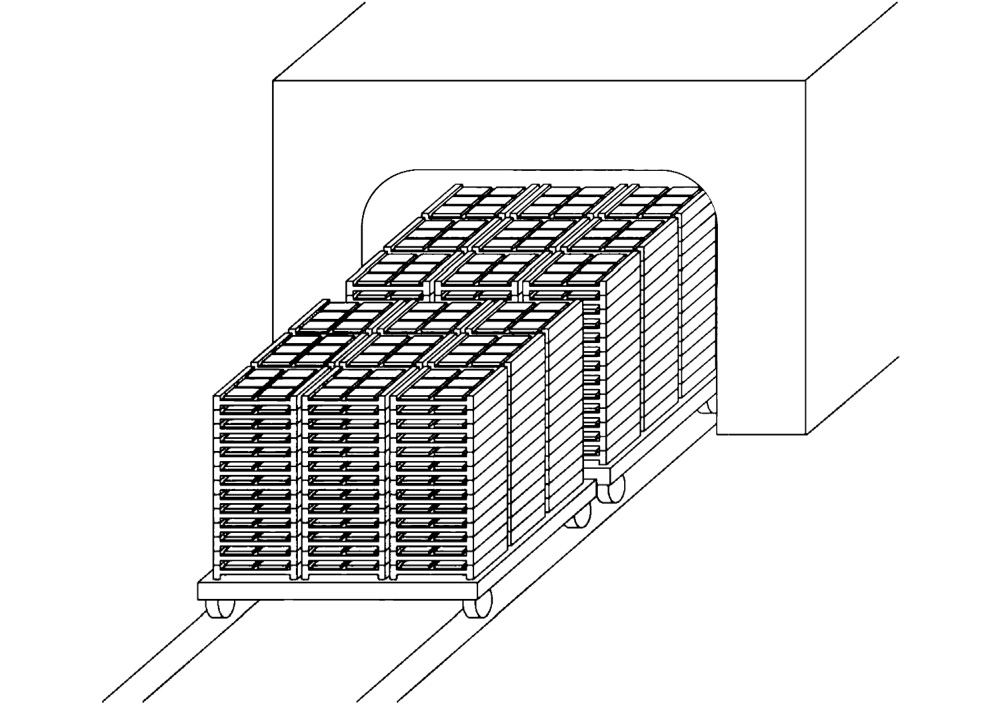

Tunnel Kiln

While slowly moving through the tunnel-like kiln over 20 to 40 hours, the cart filled with tiles passes through the preheating zone, the firing zone, and the cooling zone.

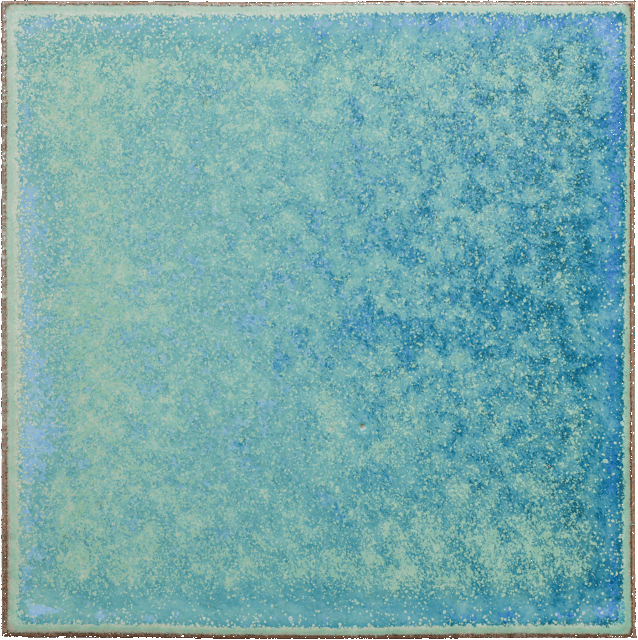

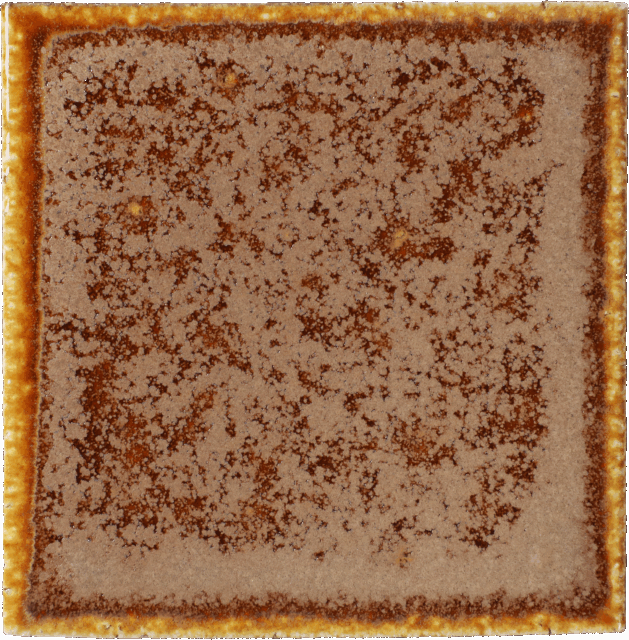

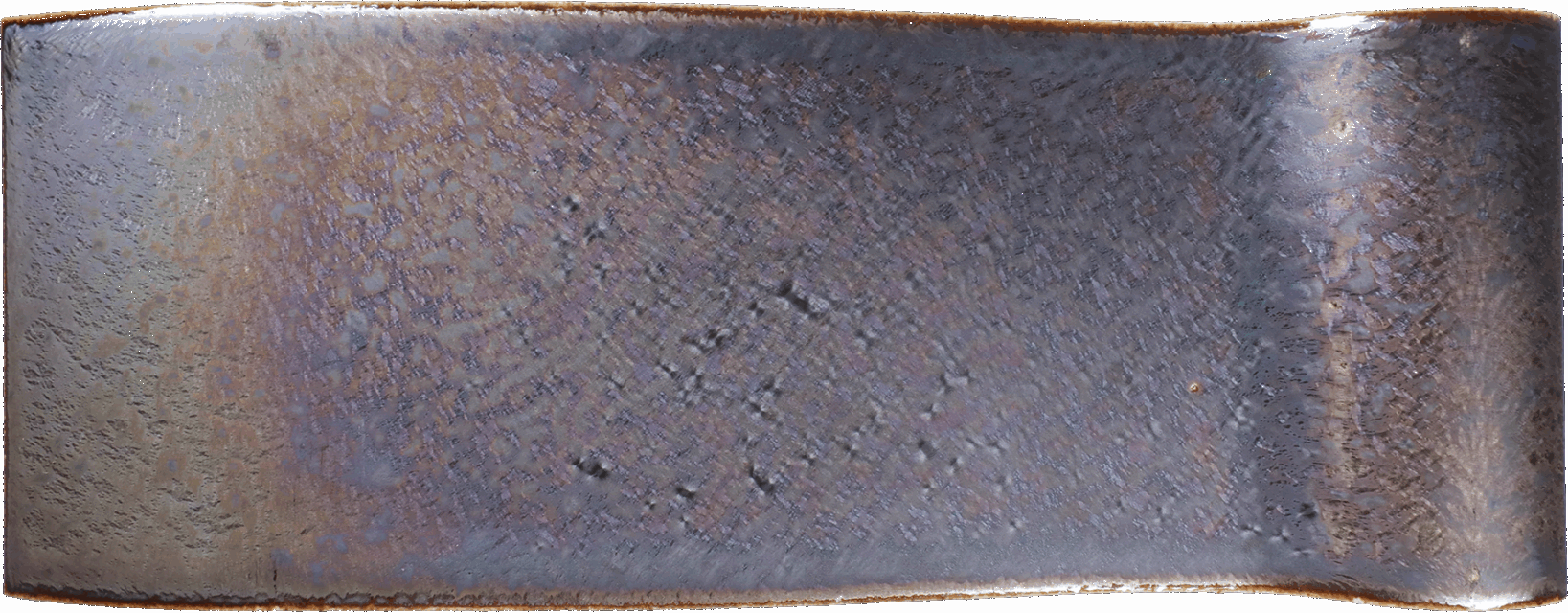

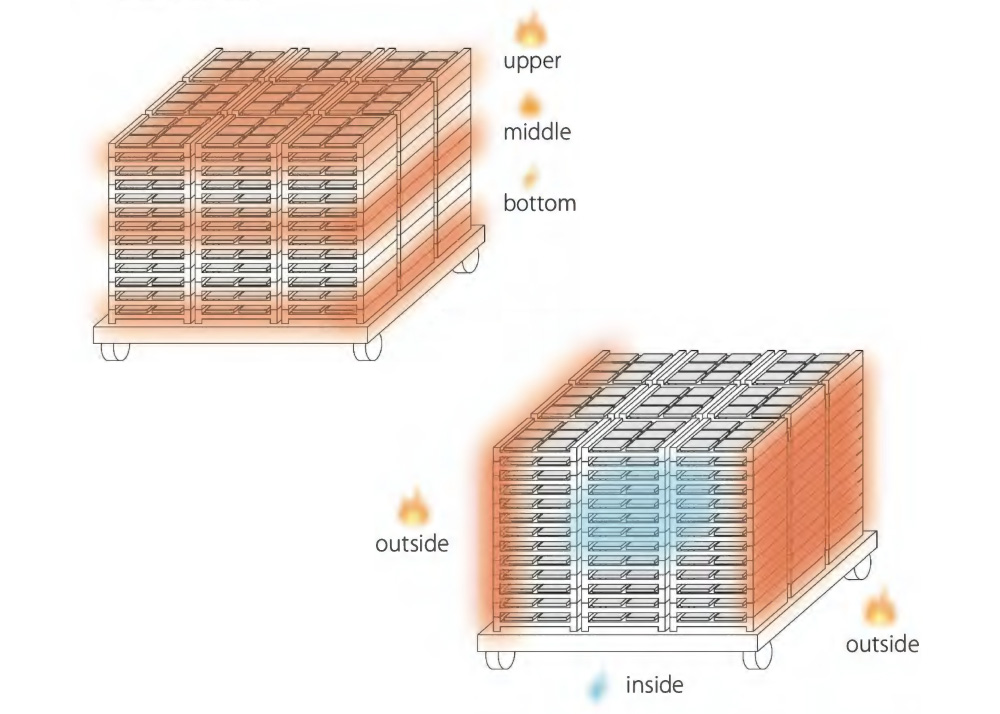

Wide Color Variation

Color variation tends to occur in tiles due to temperature differences, depending on the position of the sagger (ceramic tray) in the cart and within the kiln.

Temperature: 1200~1300℃

Temperature: 1200~1300℃Firing Time: 20~40h

Firing method

![]() Oxidation Firing

Oxidation Firing

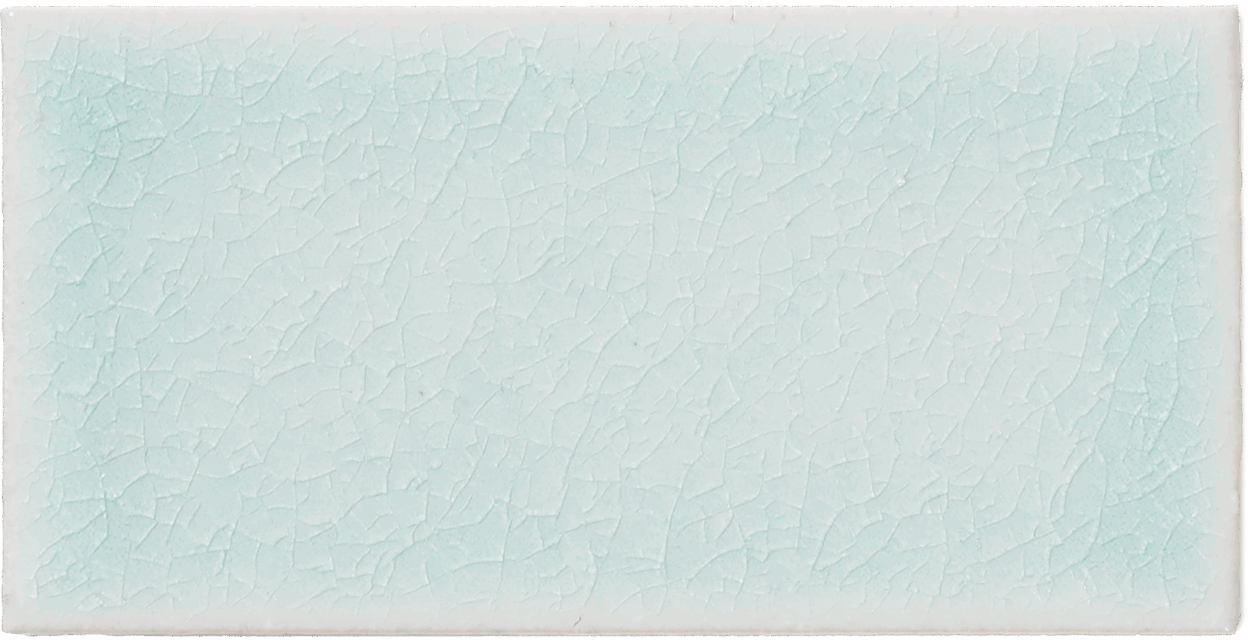

This is a firing method that ensures a full supply of oxygen through proper kiln ventilation. The metal oxides contained in the glaze and raw materials combine with oxygen to form new compounds that develop color. This method results in relatively stable and consistent coloration.

![]() Reduction Firing

Reduction Firing

Reduction firing is a method that deprives the material of oxygen by limiting the oxygen supply inside the kiln. Subtle differences in the kiln atmosphere create natural color variation and enhance the pottery-like texture of the tiles.

Production

Wet Production Tile

Wet Production Tile

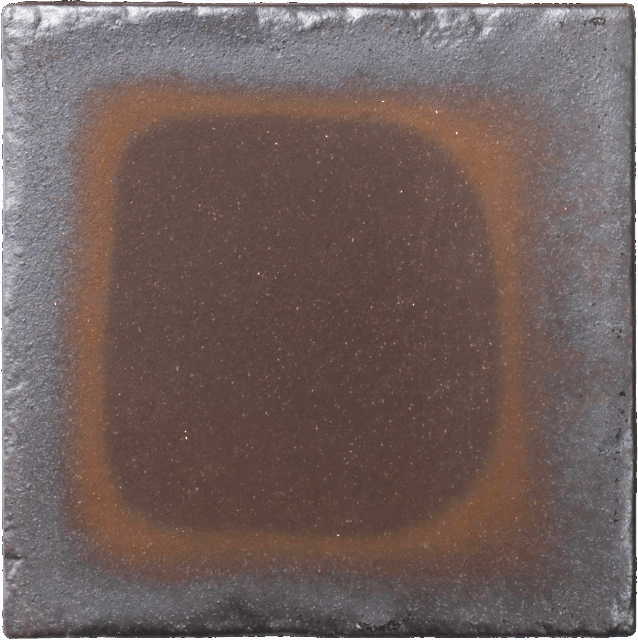

Peculiar to handmade pottery, the warm expression of wet clay is particularly attractive. Due to the high moisture content of the raw material, shrinkage and distortion are likely to occur during firing. However, this uniqueness and the unevenness in color and texture enhance the sense of presence, giving the tile a distinct charm.

![]() Dry Pressed Tile

Dry Pressed Tile

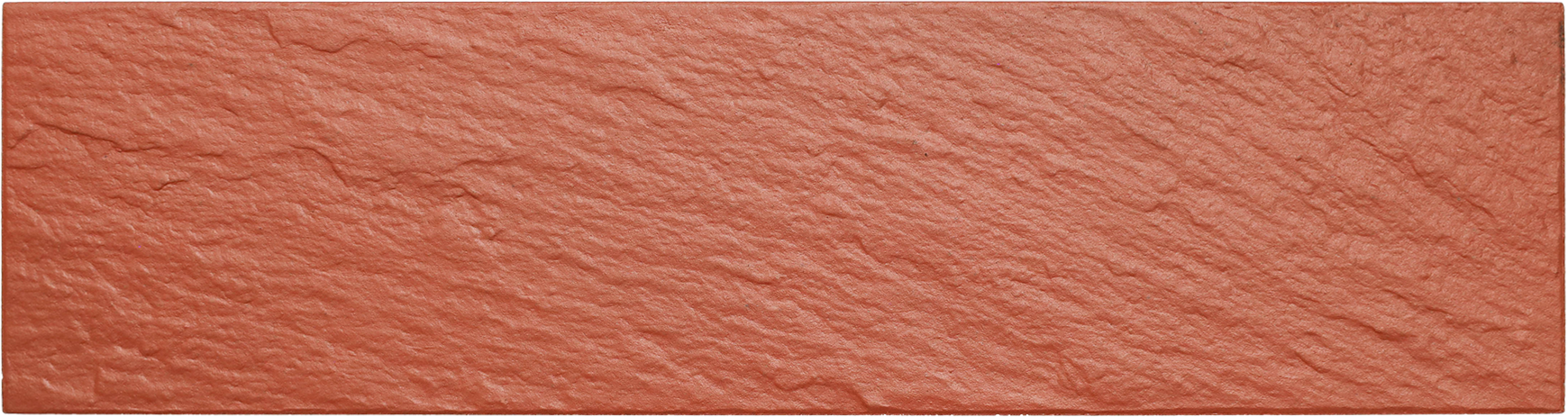

Due to the relatively short drying and firing times, the dimensional accuracy and quality of the products remain stable. Pressing powdered clay into a mold gives many of the tiles a uniform and clean texture. Recently, this process has been improved to produce products similar to wet production tiles, with a more gentle and natural appearance.

Story of Manufacturing

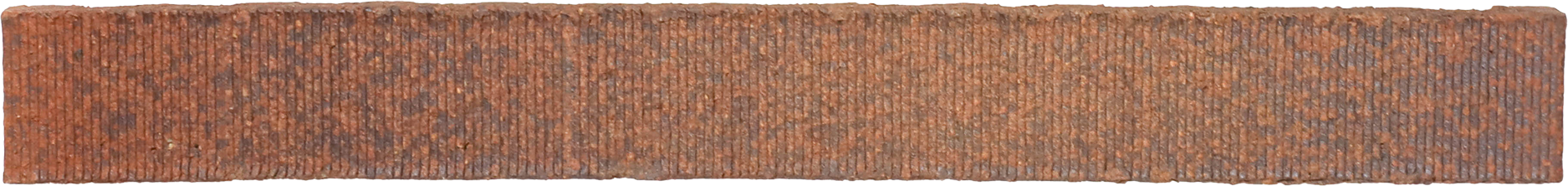

Wet Production Tile

Clay extrusion is a characteristic Tajimi method that has been used for many decades. Extruded tiles, with their variations in color and texture, have a particularly warm, handmade look that is perceived as typical of Japanese aesthetics. The process is partially automated and is also suitable for medium to large quantities.

Works: IKKEI GUEST HOUSEProducts: TAIKO

Story of Manufacturing

Dry Pressed Tile

Pressure molding is a technique often used in Japanese pottery production. In this method, dry clay powder is used instead of regular clay. Large steel molds compress the powder and form the tiles under high pressure, before the tiles are glazed and fired in a tunnel kiln.

Works: Hoshigadai Nursery SchoolProducts: MONO MOSAIC